A practical guide for factories and importers to avoid surprises and ensure efficiency.

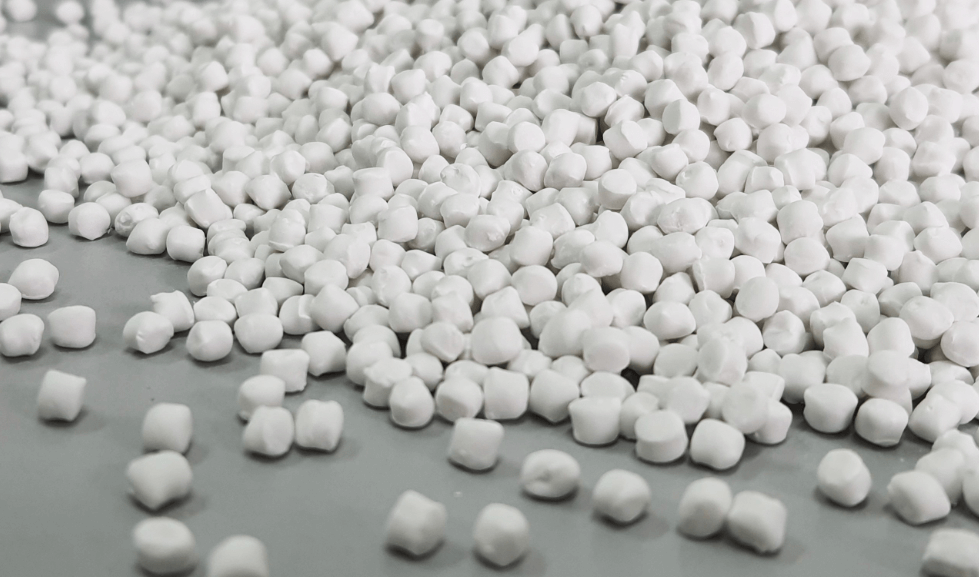

Purchasing filler masterbatch is both a technical and commercial decision. Choosing the wrong type can affect production quality, increase waste, or even damage manufacturing equipment.

For this reason, Epic offers you this simple guide to testing filler quality before purchasing, whether you are a manufacturer in Egypt or an importer abroad.

First: Why is it necessary to test the filler beforehand?

- To ensure compatibility with the polymer used (PP or PE).

- To avoid operational problems such as clogging or decomposition during extrusion.

- To determine the effect of the filler on the final product in terms of appearance, stiffness, or printability.

- To estimate the ideal loading ratio without negatively impacting product properties.

🧭 Second: Steps for testing the filler in the factory

✅ 1. Moisture Content Test

- Tool: Moisture Analyzer

- Ideal ratio: Less than 0.2%

- Excess moisture = bubbles, charring, and blockages in molds

✅ 2. Dispersion Test

- A small amount of filler is dissolved in a specific solvent or heat-tested.

- The goal: to ensure the granules are evenly distributed and free of lumps or impurities.

✅ 3. Tensile Strength Test

- Compare the final product with filler and one without filler.

- With a good filler, the pull force or ductility should not be significantly reduced.

✅ 4. Compatibility Test

- Test the filler on a real production line with the type of polymer you’re using.

- Observe the machine’s behavior: Is there excess pressure? Is there buildup?

- Observe the product: Are white spots appearing? Is the gloss significantly reduced?

✅ 5. Density Check

- The density must match the technical data provided by the supplier.

- Any discrepancy may indicate the presence of impurities or impure fillers.

Third: For importers – What to request from the supplier before purchasing

If you are an importer, ask the supplier:

- Certificate of Analysis (COA) for each batch

- A minimum 5 kg actual production sample

- Previous compliance report with other factories in your country (if applicable)

- Technical support for testing the filler on local production lines

At Epic, we provide all this and more before completing any export deal.

Fourth: Important warnings when testing fillers

- Don’t rely solely on price!

- Avoid fillers of unknown origin or without certifications of analysis.

- Don’t judge a filler by the shape of the granules alone—the appearance doesn’t reflect performance.

- Don’t use a higher loading concentration than the product label allows.

Fifth: What does Epic offer you?

- Free samples available for testing before purchase

- In-house testing labs to ensure results

- Technical support to customize the formula to suit your machine

- Complete transparency in composition and chemical analysis

Conclusion:

Testing fillers before purchasing is an essential step to protect your investment and ensure the quality of the final product. By following the steps above, you can make a sound decision based on scientific data, not just marketing promises.

Don’t risk the quality of your plant—try first, then decide.

Contact the Epic team now to request your free sample and schedule a practical test on your production line.