How do you achieve real production cost reduction without compromising the quality of the final product?

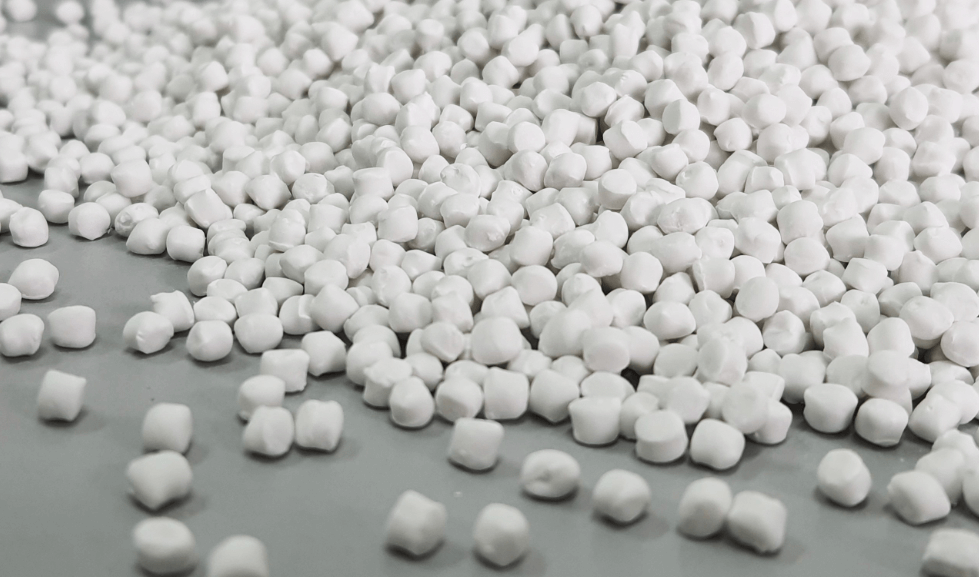

In a highly competitive market with volatile raw material prices, manufacturers are constantly looking for solutions that help them reduce costs without compromising product quality. This is where filler masterbatch comes in as one of the most powerful cost-saving tools in the plastics industry, without sacrificing performance or efficiency.

In this article, we review six key benefits of using filler masterbatch to achieve optimal production and economic results.

✅ 1. Reducing dependence on virgin polymers

One of the most significant benefits of filler masterbatch is that it can be used as a partial replacement for pure polymer (PE or PP), reducing the direct cost of raw materials, which often represent the largest portion of the product cost.

Applied example:

Using filler at a 20% loading rate can reduce raw material costs by up to 15%.

✅ 2. Improve operating smoothness and reduce energy consumption.

Professionally designed fillers, as offered by Epic, help improve material flow through machines and reduce stress on the screw and cylinder, resulting in:

- Reduced electricity consumption.

- Reduced heat requirements.

- Extended life of spare parts.

The result? More efficient production lines and lower operating costs.

✅ 3. Reducing waste and rejection

Consistent filler quality results in consistent and consistent production, reducing defective or rejected products at the end of the production line.

More saleable products, less waste = higher profits.

✅ 4. Improving the properties of the final product

Some advanced types of fillers improve:

- Heat resistance.

- Hardness or softness, depending on the formulation.

- Printable or colorable.

This allows you to produce a higher-quality product at a lower price than products that rely solely on pure raw materials.

✅ 5. Variety of formulas depending on the nature of the product.

Filler Masterbatch is available in multiple formulations that can be customized to suit:

- Packaging products (films).

- Injection molding.

- Synthetic fibers and fabrics.

- Pipes and profiles.

This means you can choose the formulation that maximizes efficiency and minimizes waste.

✅ 6. Easy to transport and store

Fillers are often more stable than raw polymers, which are sensitive to heat and humidity. This reduces:

- Damage to shipments during transportation.

- Special storage requirements.

- Unwanted environmental impact.

All of this translates into significant logistical savings across the supply chain.

What does Epic offer you?

At Epic, we manufacture Masterbatch Fillers with precise scientific formulas to provide:

- Highest efficiency and reduced costs.

- Perfect compatibility with production lines.

- Technical support to optimize the filler’s application in your specific formulation.

Conclusion:

Filler Masterbatch is more than just a filler; it’s a strategic tool for reducing costs, increasing profits, and improving production quality. If you’re looking for a smart and stable way to manage factory expenses, it’s time to try Epic’s filler solutions.

Contact us now to test a free sample of the type best suited for your industrial application.